Extraction Condensing Steam Turbine Pdf

Condensing steam turbines are most commonly found in electrical power plants. These steam turbine exhaust steam in a partially condensed state, typically of a quality near 90%, at a pressure well below atmospheric to a condenser. The steam turbine operates on basic principles of thermodynamics using the part of the Rankine cycle. Superheated vapor (or dry saturated vapor, depending on application) enters the turbine, after it having exited the boiler, at high temperature and high pressure. The high heat/pressure steam is converted into kinetic energy using a nozzle (a fixed nozzle in an impulse type turbine or the fixed blades in a reaction type turbine). Once the steam has exited the nozzle it is moving at high velocity and is sent to the blades of the turbine. A force is created on the blades due to the pressure of the vapor on the blades causing them to move. Oxford Practice Tests For The Toeic Test on this page. A generator or other such device can be placed on the shaft, and the energy that was in the vapor can now be stored and used. The gas exits the turbine as a saturated vapor (or liquid-vapor mix depending on application) at a lower temperature and pressure than it entered with and is sent to the condenser to be cooled. If we look at the first law we can find an equation comparing the rate at which work is developed per unit mass.

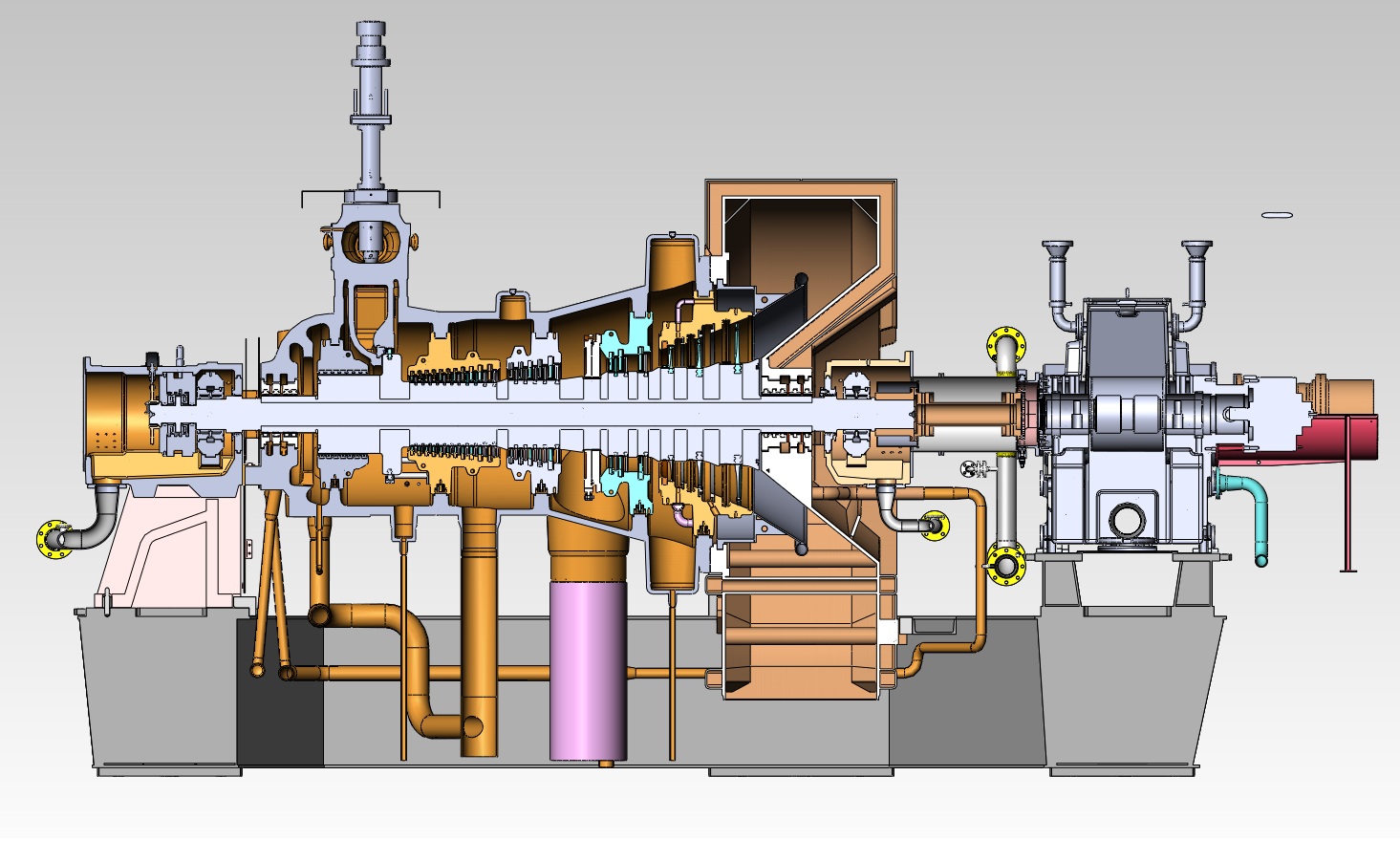

To maximize turbine efficiency the steam is expanded, doing work, in a number of stages. These stages are characterized by how the energy is extracted from them and are known as either impulse or reaction turbines. Most steam turbines use a mixture of the reaction and impulse designs: each stage behaves as either one or the other, but the overall turbine uses both. Typically, higher pressure sections are reaction type and lower pressure stages are impulse type. Extracting type or condensing type steam turbines are common in all applications. In an extracting type turbine, steam is released from various stages of the turbine, and used for industrial process needs or sent to boiler feed water heaters to improve overall cycle efficiency. Grizzly Tsc-10l Manual here.

Extraction flows may be controlled with a valve, or left uncontrolled. Icewind Dale Ii V.2.01 Patch.

Applications are classified as either non-condensing or extraction. A non-condensing turbine, also. Combined Heat and Power Technology Fact Sheets Series: Steam. 1.3.3 Automatic extraction condensing 15 1.3.4 Basic steam control considerations 18. Multistage Steam Turbines 309 15.1 Approximate Steam Rates 309.